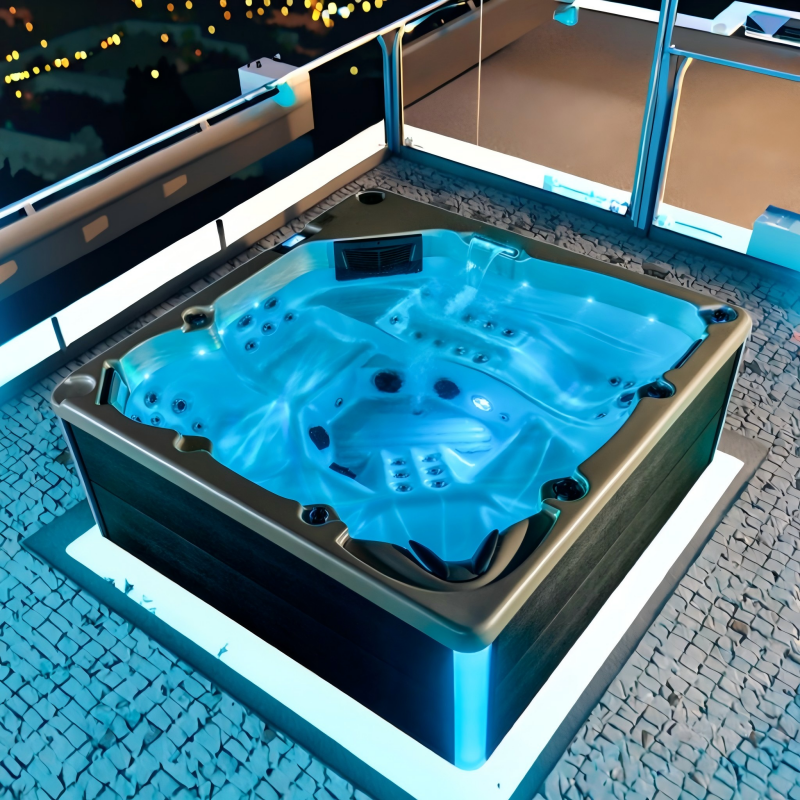

When building a spa jacuzzi tub, is sand needed under the tub?

2026-01-28 15:30When installing or building a spa jacuzzi tub, the treatment of the foundation structure is a crucial step. Many users ask a common but critical question: "When building a spa jacuzzi tub, is sand needed under the tub?"

This question often involves load-bearing structure, foundation stability, drainage performance, service life, and safety issues. Therefore, to determine whether sand needs to be laid under the spa jacuzzi tub, a comprehensive analysis from multiple perspectives is required, including material structure, installation standards, tub weight, and support methods.

This article will answer this question in a thorough and systematic way, helping users truly understand the installation requirements of a spa jacuzzi tub and whether sand is suitable as its underlying support layer.

Is sand absolutely necessary under a spa jacuzzi tub?

Simple answer: Not necessarily, and in most cases, it is not recommended to use sand as the main support layer for a spa jacuzzi tub.

However, different installation methods, different ground conditions, and different spa jacuzzi tub structures may all affect whether sand is needed. Therefore, further analysis is required.

Can sand be used as a foundation material for a spa jacuzzi tub?

Many users believe that sand is a common ground leveling material, so they may consider using it when installing a spa jacuzzi tub. In traditional bathtub installations, sand is sometimes used to fill the gap between the ground and the bottom of the bathtub to enhance stability.

However, spa jacuzzi tubs are significantly different from ordinary bathtubs, for example:

• More complex structure

• Heavier equipment weight

• Extremely heavy load when filled with water

• Contains equipment such as water pumps, motors, and heaters

• Requires long-term stable support

Therefore, sand as a filling material may not be suitable for spa jacuzzi tubs, which is why many professional installation guides explicitly state that sand is not recommended.

Why do many spa jacuzzi tub manufacturers not recommend using sand as bottom support?

The following will provide an in-depth analysis from the perspectives of engineering structure and material properties.

1. Sand is easily moved and cannot maintain a stable structure long-term

Sand is a fluid material and will move or sink due to:

• Heavy pressure

• Water penetration

• Vibration (e.g., from pump operation)

• Temperature changes

• Pressure from surrounding soil

This is very unfavorable for a spa jacuzzi tub because the tub body requires:

• Long-term stable weight bearing

• Prevention of bottom deformation

• Stability during equipment operation

When the sand loses its flatness, it leads to uneven support at the bottom of the tub, and can even affect the stability of the massage nozzles, pipes, and base structure.

2. Spa jacuzzi tubs are extremely heavy, and sand poses a high risk for weight bearing

A typical 4-6 person spa jacuzzi tub, when filled with water, can weigh up to:

• 1,000–2,000 kilograms (or even more)

Under heavy pressure, the sand may be squeezed to the edges, causing the bottom to experience:

• Collapse

• Local cavities

• Irregular support points

This can lead to stress points in the tub, causing cracks or deformation.

3. Sand softens or washes away easily when wet

Outdoor spa jacuzzi tubs are often exposed to:

• Rainwater

• Ground moisture

• Water from cleaning

Once sand becomes wet, its structural stability decreases significantly, and it can even be washed away. This problem is more pronounced in humid areas and can lead to base collapse.

4. Sand is not conducive to drainage and bottom ventilation

Many spa jacuzzi tub installation guides emphasize:

• The bottom should be kept dry

• The support material should be well-ventilated

• A good drainage slope is required

Sand easily retains moisture, causing the bottom to remain damp for extended periods, which can affect:

• Equipment lifespan

• Corrosion resistance of the metal base

• Air humidity near the motor

If sand is used, excellent moisture-proofing measures are necessary to compensate for the shortcomings, but this is not easy for the average user to achieve.

5. Sand does not provide structural reinforcement

Spa jacuzzi tubs are usually installed on:

• Concrete foundations

• Wooden platforms

• Steel structure platforms

• Pressure-treated wood flooring

These foundation materials are rigid, while sand does not provide structural support. Therefore, most professional guidelines do not recommend sand as a base foundation.

If sand is not suitable as a support layer, what should be placed under a spa jacuzzi tub?

According to industry standards, the most suitable base materials for a spa jacuzzi tub usually include:

1. Concrete Platform (Most Recommended)

Concrete is the most stable and durable support structure.

Advantages:

• Extremely high load-bearing capacity

• Will not deform

• Unaffected by moisture

• Maintains flatness for a long time

• Suitable for outdoor installation

• Minimizes vibration from equipment operation

This is the strongly recommended option by most professional manufacturers (including major brands).

2. Pressure-Treated Wood Platform

Many outdoor platforms and patio structures use wooden platforms.

Advantages:

• Strong load-bearing capacity

• Flexible installation

• Good ventilation

• Aesthetically pleasing appearance

However, the wood must meet:

• Pressure treatment requirements

• Corrosion resistance standards

• Sufficient beams and support points

To ensure it can withstand the weight of the spa jacuzzi tub.

3. Steel Support System

Some spa jacuzzi tubs are installed on:

• Steel platforms

• Composite support frames

• Metal-clad foundations

Advantages:

• High rigidity

• High durability

• Even support

• Not easily deformed

This method is often used in professional engineering projects.

4. Compacted Gravel Layer (Only for Enhanced Drainage)

Gravel can be used for:

• Building a drainage foundation

• Providing a permeable base layer

• Preventing water accumulation from affecting the bottom structure

However, the gravel layer must be compacted and used only as a base layer, not as the direct load-bearing surface for the bathtub.

In other words, a concrete or other solid surface is still needed above the gravel layer.

Since sand is not recommended, under what circumstances can sand be used to a limited extent?

Although sand is not recommended for load-bearing purposes, in some special cases, sand can be used as an auxiliary material.

For example:

• Used to fill local gaps

• Used for initial leveling (a hard foundation is still needed above)

• Used as a base layer under a drainage slope

• Used to assist in adjusting height during concrete construction (non-load-bearing parts)

However, in any case, sand cannot be used as the sole load-bearing material.

Why do some old installation methods recommend placing sand under the bathtub?

In the past, some traditional bathtubs (non-spa jacuzzi tubs) were installed using sand because:

• Ordinary bathtubs are lightweight

• There is no equipment vibration

• The water volume is small

• They do not need to withstand high gravitational loads for extended periods

• There are no built-in motors, pumps, and jet systems

However, modern spa jacuzzi tubs are completely different:

• They use heavier acrylic shells

• They contain equipment such as pumps and heaters

• They have a larger water capacity

• They require a flat and sturdy support surface

• They experience continuous vibration and operating loads

Therefore, traditional methods are not applicable.

What risks might arise from using sand as a base for a spa jacuzzi tub?

The following problems may occur:

• Unstable foundation, leading to the bathtub tilting

• Global or local subsidence at the bottom

• Pipeline deformation due to pressure

• Failure of the jet system

• Cracks in the acrylic shell

• Increased equipment noise

• Accelerated motor wear due to tilting

• Corrosion of the metal frame due to long-term dampness

• Safety hazards (especially around high-power electrical equipment)

These risks indicate that sand is not an ideal foundation.

Does LOVIA SPA support customized packaging for retail purposes?

Yes. LOVIA SPA offers flexible packaging options such as heavy-duty wooden crates, branded cartons, waterproof inner protection, and customized labeling. Retail buyers can personalize packaging to match their brand’s visual identity. Our factory ensures safe, stable, and visually appealing packaging suitable for store displays or direct delivery.

Wholesale customers can buy upgraded packaging at favorable prices and request quotes tailored to their branding needs.